EURO BASE

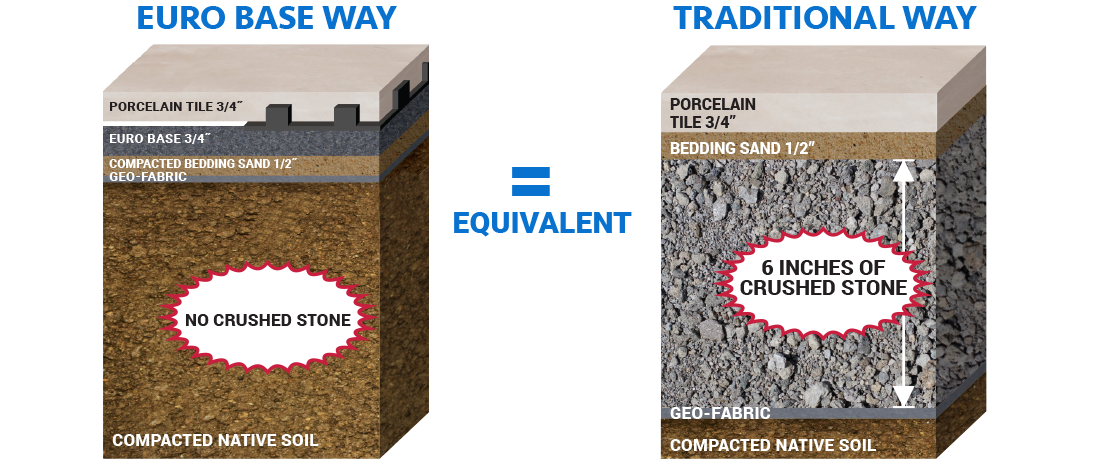

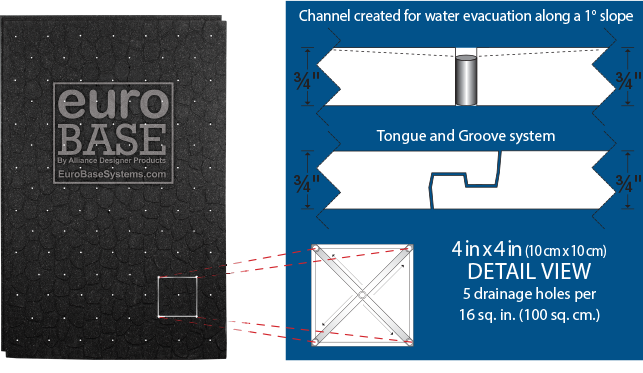

EURO BASE is an evolution of foundation technology, which saves you time, labor and money. It is manufactured for pedestrian applications such as: patios, pool decks, walkways, 18″ (45 cm) seating walls and fire pits, allowing you to clearly define your spaces and highlight the focal points of the dream staycation area. Designed with a tongue and groove system, EURO BASE is easy to install. A single EURO BASE panel is also equivalent to 130 kg (288 lb) of crushed stone, saving you a minimum of 6″ (15 cm) of additional excavation. The EURO BASE drains water through channels and is made from lightweight, high density polypropylene. Environmentally friendly, EURO BASE is 100% recyclable, extremely durable and EURO BASE does not degrade in the soil when buried.

FOR CONCRETE PAVERS,

PORCELAIN TILES AND NATURAL STONES

- Patios, sidewalks, walkways, paths and pool surrounds

- 18″ (45 cm) seating walls and fire pits

- Concrete pavers, natural or wet cast stones

- Porcelain tiles and slabs

- Save 6″ (15 cm) of additional excavation

- Save 6″ (15 cm) of compacted crushed stone

- 50% savings on the costs of soil excavation

- Save the cost of truck and driver on the road

- Avoids costly unloading and dumping fees

- Reduces labor costs by a minimum of 20%

- Reduces wear and tear on machinery

- Reduces overall installation time

- Reduces unnecessary excavation

- Project completed faster and easier

- Euro Base panels help transfer dynamic and static loads

- Helps to combat the labor shortage

- Take Note: For pedestrian use only

Coverage per Euro Base Unit

23.5 in x 35.5 in = 5.79 sq ft, ¾ in thick, weight = 1.32 lbs each

59.7 cm x 90.2 cm = 0.54 sq m, 19 mm thick, weight = 0.6 kg each

| Product | Size | Units per Pack | Units per Pallet |

|---|---|---|---|

| EURO BASE | 24.25″ x 36.25″= 6.1 sq. ft. / 61.5 cm x 92 cm= 0.566 sq. m. | 10 | 120 |

What would you rather carry 1440 lb of crushed stones or 6.6 lb of Euro Base? It's a no brainer!

5 Euro Base = 28.95 sq. ft. (2.7 sq. m.) and weighs 6.6 lb (3 kg) = Installed within minutes!

12 wheelbarrows of crushed stone = 28.95 sq. ft. (2.7 sq. m.) X 6″ (15 cm) and weighs 1440 lb (653 kg) = Many hours of work!

ENGINEERING

Euro Base is environmentally friendly, engineered to return water to the native soil due to the evacuation channels incorporated in the euro base. It will never leach chemicals or degrade in the native soil for over 100 years.

Euro Base engineered to support static or dynamic load

EURO BASE SUPPORTS A DYNAMIC LOAD OF UP TO

8 PSI (55.2 KPA) OR 1152 LB (523 KG) ON A 12″ X 12″ (30 X 30 CM) PAVER

Better Load Transfer

Mechanical Resistance

Drainage Features

Freeze and Thaw protection

Mechanical Resistance

Alliance Designer Products Inc. has introduced to the market a revolutionary technology that will save time, labor and money when installing concrete pavers and natural stones.

With the new Euro Base® panel, you can save 6 inches of extra excavation, long hours for installation and the transportation of tons of aggregate.

This technology exhibits the polypropylene memory characteristics and allows the material to retain its original shape. Alliance Designer Products Inc. is now using this technology in their Euro Base® panel for the hardscaping industry.

An exhaustive and serious evaluation was made in collaboration with the Université du Québec’s engineering institute (ETS), in the laboratory of their Pavements and bituminous materials department, in order to characterize compare the Euro Base® panels to a traditional method of paving stone installation with aggregate.

Drainage Features

The results obtained during the “Bench test” study on a concrete paver system with a granular base (standard 6 inches of aggregate), versus the Euro Base® panel as a base are very interesting. The main reason for using gravel aggregate (crushed gravel) in the traditional method is to allow for water drainage, which prevents frost from heaving your pavers. For proper drainage, each Euro Base® panel is equipped with channels for water evacuation along a 1 degree slope as well as 5 drainage holes per 16 sq. in. Also, every Euro Base® panel (1.32 lbs) will replace 288 lbs of compacted aggregate. When using Dekkorscape Polymeric Sand, water will run off the paved surface if a minimum of 1° slope is respected.

Freeze and Thaw protection

Since the Euro Base® panels have a high thermal resistance (it would take nearly 15.7 inches of 0-3/4” dry stone, compacted to a porosity of 20% to equal the insulation provided by a single layer of Euro Base® panels), it can be assumed that there would be better frost protection with the Euro Base® than with the usual additional 6-inch aggregate base. In this case, similar movement for both of these systems would be observed after freeze-thaw cycles. The system with the Euro Base® panels works best for patios and walking paths made with concrete pavers. The subgrade soil should be compacted to at least 95% of the modified Proctor density; a geotextile fabric is needed on top of the subgrade and bedding sand should be used to ensure a smooth and uniform surface.

One Euro Base panel acts like 18˝ of crushed stone as a thermal blanket. It is 3 times more effective than crushed stone as an insulator thus significantly reducing freeze and thaw cycles.

Conclusions from results obtained by ÉTS* when comparing Euro Base system versus traditional granular base system.

- Euro Base can replace a traditional granular base.

- Euro Base is equivalent to a traditional granular base under static and dynamic loads.

- There would be much better frost protection with Euro Base system.

*École de technologie supérieure (or ÉTS) is part of the Université de Québec.

Download the University Reports

INSTALLATION INSTRUCTIONS

Please follow ICPI Tech Spec 2 & 9 specifications for compaction regulations

Step 1 • Excavation of the new Euro Tile area

Excavate the new Euro Base area. The depth required is calculated by adding Porcelain Tile height, Euro Base, bedding sand, plus any soft organic material that has to be removed. Excavate the perimeter an extra 6″ (15 cm) wider on all sides than the tile area required.

Step 2 • Levelling and compacting of the base

(A) Ensure a slope of at least 1 degree away from any structure, such as a house.

(B) • The native soil needs to be compacted using a plate compactor or hand tamper.

Step 3 • Addition of geo-fabric, levelling and compacted bedding sand

(A) • Lay down a non-woven geo-fabric and cover the entire excavated area.

(B) • Spread an even layer of sand to a depth of maximum 3/4 inch (19 mm) • The levelling and compacting the bedding sand will be the last step prior to installing the Euro Base.

(C) • Water the sand prior to using a hand compactor and/or plate compactor, compact the 3/4 inch (19 mm) of bedding sand until you obtain a final height of 1⁄2 inch (13 mm) of compacted bedding sand, that should reflect the final tiled surface.

Step 4 • Installation of the Euro Base

Make sure to install the Euro Base on the extended excavation area (total excavation should be 6 inches [15 cm] wider on each side than the final tiled area).

• Start laying the Euro Base units ensuring Euro Base interlocks with the tongue & groove system.

Step 5 • Installation of Porcelain tile and Euro Spacer

Euro Spacers should receive a generous amount of Euro XP glue on each quadrant. Install the Porcelain Tile on the Euro Spacer, apply pressure or tap the tiles with a rubber mallet at all corners. This will ensure that the tiles are adhering to the Euro Spacer. The Euro Spacer will be left in the tile installation permanently, ensuring proper alignment and stability of your project for years to come.

Step 6 • Installation of Euro Tile Edge and Euro Base Screws

Install Euro Tile Edge on the Euro Base using Euro Base Screws, make sure that Euro Tile Edge rests firmly against the tiles. Use Euro Base Screws at every second hole.

Step 7 • Sweeping, compacting and blowing of the Euro tile Sand

(A) • When emptying the bag of EURO TILE SAND, spread it onto the dry, tiled surface.• When sweeping the EURO TILE SAND, spread it over a small area before moving onto the next, while making sure to fill in the joints.

(B) • It is now time to compact the sand into the joints using a roller compactor or rubber mallet. Do not use a plate compactor. Repeat filling and compacting of the tile joints. Finally, sweep the surface with a fine bristle broom and remove all excess sand. • Ensure the sand is 1/8 inch (3 mm) lower than the tile chamfers

(C) • Finally, use a blower to blow off all sand residue laying on the tile surface.

Step 8 • Euro Tile Sand water activation steps

(A) • Shower water on a specific area of 100 sq.ft., wait no longer than 2 to 3 minutes.

(B) • Shower and rinse simultaneously on a section of approximately 100 sq. ft. so as to eliminate any EURO TILE SAND residue left on the tiles. Any EURO TILE SAND residue should go directly into the tiled joints. Wait no longer than 2 to 3 minutes.

(C) • Shower and rinse simultaneously, so as to eliminate any EURO TILE SAND residue. Any residue should go directly into the tiled joints. However, stop showering when you see water retention on the tiled joints. Wait no longer than 2 to 3 minutes. Note: Repeat the directions of STEPS 8a to 8c for all other areas that have not been showered with water.

(D) • Use a leaf blower to remove any excess water remaining on the tiled crevices. This blowing action is necessary to help remove any remaining EURO TILE SAND residue left on tiled surfaces from the previous steps.

WATER ACTIVATION (IMPORTANT NOTES)

- Work in manageable sections, ideally about 100 sq. ft. at a time, depending on temperature.

- Do not allow EURO TILE SAND to wash out of joint.

- Never allow tiled surface to dry out during the water activation phase.

- Watering must be started at the lowest point of the tiled surface.

- Use a watering gun connected to a hose. Setting should be set to shower.

IMPORTANT: The water used in steps 8a to 8c will activate a bonding action as well as condensing EURO TILE SAND in the joints. It is important to water the EURO TILE SAND a total of 3 times, as per steps 8a, 8b and 8c. To little water will not properly activate the EURO TILE SAND and will reduce the final performance.

MOSS: Euro Tile Sand will not cause nor prevent moss, mold or mildew. Moss, mold and mildew are caused by certain on site conditions including excess moisture, shade, absence of ventilation, inadequate cleaning or maintenance, presence of soil or other organic debris left on the product.